Concrete Bases and Footer for a Seismic resistent House in the Osa Peninsula need to be made with the right Project, Material, Tools and Skill as Rearewood General Contractor does

Few Words over Concrete Elements in our Constructions

Starting with the good approach makes things easier. Is our normal process of work to start with a detailed 3Dimensional model of the House, Cabin, Restaurant, etc. we will build, for to understand exactly how it will appears at the end of our work, and have the chance to calculate, with extreme, precision the quantity and size of every element that will be part of the Construction.

This way to proceed, helps the Owner to have, from the very first step of our collaboration, the vision of what we will do and the cost, with an approximation inside the 10%, due to variables of market and norms, of the whole operation. Concrete, for us, is important as much wood is, because, despite the fact that, often, is not the most scenic part of the Building, it is, often, responsible for the strength and durability of it.

Compacting the Soil under the Bases of the Walls is fundamental for a good quality Concrete Footers

Soil Compacting is not important only for the bases and the footers, but for the filling of a Slab Floor too, for to avoid having some air chamber underneath, due to the filling shrinking

A good Footer or a Floor, made with quality gravel, sand, cement and iron bars, is important, as the underneath soil is. Breaking and crackings will appear soon in the concrete walls and floor if the subsoil had not been properly compacted with mechanical tools, as we does. The old style system, still widely diffused here in the Osa Peninsula, based over the use of a wooden stump left to fall on the ground by a worker, doesn’t produce the necessary density of the gravel or dirt.

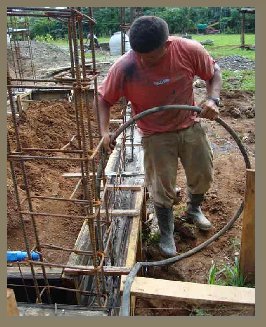

Good Quality and Correct positioning of the Form Wood Assure a Good quality and resistance of the Concrete Footers

The Use of Vibrators during the operation of Concrete Pouring, increase a lot the resistance of the final element and the smoothness of the surface

The good quality of the Form Panels, and the correct positioning of them, produce High Quality Concrete Columns and Beams, with a good quality surface

After having obtained a good quality, well compacted bottom where to start building, the use of high quality form elements is important for to obtain dimensional and structural correct retaining walls and foundations. We choose to use Plywood paneled form elements because they offer several advantages over the rough, fresh cut, poor quality form board normally used by local builder : -they are lasting ten times what a rough board does, but costs only the double -they produce straight, plane concrete surface -they allow the use of concrete vibrators – no forest trees are slashed for to produce one time use boards -reduce the time of form assembling and final cost of the building

Exact Shape of the iron cages and the right amount of correctly sized rebars, combined with the perfect mix of concrete produce high resistance columns and beams

High Quality Concrete with Chemicals that enhance the fluidity and the resistance

The correct Mix of Cement, Gravel, Sand and Chemicals Additives produce a perfect surface Concrete with great Mechanic resistance

Another important element that is part, but not visible at all, of the concrete foundations and retaining walls, are the chemical additive used in the concrete mix. Depending by the function of the concrete element, different additive must be used, for to help the mix to harden better, faster or slower, adding waterproofing or hardness, etc. etc. all details that can make the difference among a functionally and safe, let’s say, infinite horizon swimming pool wall or a simple retaining wall along the bank of an unpredictable creek.

When we first arrive here, in the Osa Peninsula, almost twentyfive years ago, the only anchoring system known, was a piece of rebar, in the most sophisticated situation with an end bend, placed inside the concrete during the pouring phase. With that ” pin” everything was, supposedly , anchored to the concrete, doesn’t matter if the wooden elements were designed for to resist to down or up, side or diagonal forces, often with tremendous mistakes resulting in roof and related structure fall. After several year spent in Italy, building Big Laminated Beams Structures and having to apply the strict DIN rules, that specifies every little details of the wooden construction size and distribution of screws, bolts, plates, pins, etc. , this looked like another planet, and we start teaching to local worker how to apply ” our” rules, often defying their smiles and laughs.

Threaded bars inserted in the concrete bases during the pouring operation need an high grade of Precision, but guarantee the better resistance

Concrete to Wood Column Iron Connection Element that allow transfer the resistance of the base to the wooden Column without creating weak points in the structure

Metal Connection Elements fixed to a concrete column with the use of High Quality metal Expandable plugs, need an High Quality Concrete for to be efficient

Now, after that, some of them, realized the advantages of to build with ” northern” technique, the use of threaded bars had become quite common, instead the iron bars, but the use of custom made metal connection elements is still almost our exclusivity, and the use of steel expandable plugs is something that only with the high quality of our concrete has some sense, being completely insufficient if placed inside the current concrete elements poured without all the care we put in them.

In the last years the use of prefabricated beams and foam elements for the creation of a suspended floor had become easily available in the country, and we started utilizing it in our building. This technique allow us to save a lot of time in the creation of these components of the building, and in the same time reduce the use of form wood and posts for to sustain the inter-floor during the time it cures. It is a little step toward a more sustainable way to build, and save a lot of time, leaving the underneath area available for the prosecution of the works, almost immediately after the pouring operations.

Interfloor Pretensed Concrete beams with the Foam blocks filling is a great solution for the realization of suspended floors, in a short time.

The use of the Interfloor system reduces a lot the amount of concrete needed, creating a much lighter structure and produce a lot of saving on the materials and their transport.

The underneath of an Interfloor slab becomes available for to work almost immediately after the pouring of the concrete fluid

Once the concrete foundations, the slabs, the columns and the walls are completed, then is when the most interesting part of the Game starts: the Wood Structure, Ceiling, Doors and Windows, Stairs and Wood Flooring. Here is where our Constructions, House or Lodges and everything in between, get that touch that makes them impossible to confuse with the rest of the local ones.

Here, in the combination of Ancient Construction techniques form several Cultures of the World, and the use of Local Wood, collected as Fallen Threes in the forest, or harvested in Plantation in the Country, is where we are able to create structures and finishes that get the stronger mechanical resistance for to resist to the strong Earthquakes and the attack of natural agents like bugs, fungi and humidity of this area of the World.

Beauty is always our first goal, but we can’t forget the resistance and functionality of the wooden or Concrete Structures, and for obtain the correct balance we use the last achievements in term of connection, gluing and anchoring components, avoiding that their use compromises the elegance of the details.

Doors and Windows Laminated Arched Frames Built by Rarewood General Contractor in Puerto Jimenez Osa Peninsula

Reticular Wooden Beam made by Rarewood General Constructor in Puerto Jimenez Osa Peninsula

The Workshop of Rarewood General Contractor in Puerto Jimenez Osa Peninsula

All the Structural and Finishing elements that are part of the Houses, Lodges, or Furniture we Build or Make, are processed in our workshop, guaranteeing the respect of the measures and characteristics of quality that we want our final projects will show, no weak or imperfect element will be produce and, much less, used.